For those devoted students of Bob Bundschuh's Pedicar, the title of this post may seem presumptous. After all, the Pedicar is a high-water mark in the production of a practical human-powered commuter vehicle. However,we know a lot more about human power than in 1973, when the top speed of a rider sprinting on a bicycle was about 45mph and the first edition of "Bicycling Science" was a year in the future. So the Pedicar's linear transmission was based on a lack of understanding of human-power generation and the speed potential of this type of vehicle was underestimated by about half. There is significant potential to improve a Pedicar-type vehicle's performance and still meet the design criteria below.

Human Powered Commuter Vehicle Criteria

Human Powered Commuter Vehicle Criteria

2. Statically Stable

3. Reasonable Cruise Speed

4. Cargo Carrying Capacity

5. No Wider than a Bicycle

6. Same Height as an Auto

7. Comfortable posture and ease of entry

8. Two-wheel drive

9. Car-type Wheels

10. Electric Assist for Hills

It should be no surprise that when I compiled the HPCV list above, I had quite a bit of time invested in building a proof-of-concept vehicle that I felt would satisfy these criteria. Early on, the vehicle was christened the EcoVia.

The broad approach was a banking-recumbent tricycle with two-wheel drive.

Four functions had to be distributed among the wheels. These are steering, driving, banking and braking. Each wheel had its own caliper brake, so braking did not affect the distribution of the other functions. Driving and steering the same wheels required the complexity of some type of constant-velocity coupling, so steering and driving were separated. From this decision, since two wheels were driven, the single wheel did the steering. The two driven wheels did the banking. To eliminate the interference between the cranks and the steered wheel the steered wheel was placed in the rear, resulting in a rear-steering tricycle.

EcoVia 1.4

EcoVia 1.4

Below are several sketches of the expected body shape for the enclosed vehicle.

Now, rear-steering tricycles have inherent stability issues. (Refer to “Bucky and the Urbee”, below). These issues were exacerbated by the requirement that the vehicle lean into the turns.

Recall that vehicle lean in a stable turn is an inverse function of the steering angle and a direct function of the square of the speed. (Refer to “The Drymer and Varna Lean Forward”, below). Now for a HPCV, without any electronic banking control, there are three approaches to control leaning. The best and simplest approach, for tricycles that are inherently stable, is free leaning, where the vehicle balances like a bicycle and leans accordingly. Rear-steering trikes are not inherently stable so this approach was not attempted. One of the remaining approaches is to control steering and leaning separately. This can be ergonomically challenging in addition to requiring twice the typical steering hardware. The remaining approach is to link steering and leaning to one control. This, while simpler than the former, usually results in too much lean at higher speeds and not enough lean at lower speeds. The approach I used was a combination of these methods. More specific details a bit later…

The heart of the dual-drive leaning design is the use of a dual-function central driveshaft made up of three concentric tube assemblies.

A chain from the cranks turns the drive shaft proper, which is made from a thick-walled, 1” dia. tube. The free-hub body is brazed directly to the drive shaft without a ratchet. On each outboard end of the drive shaft, a 16t freewheel is attached. The left side used a convention right-handed freewheel and the right side used a 16t Southpaw freewheel. This freewheel had a reversed ratchet and a left-handed thread to prevent it from unscrewing during driving. Second and third chains connect the freewheels to 14t fixed gears on the drive wheels. The fixed gears were glued to the hubs using red Loctite, again to prevent the cog on the right wheel from unscrewing during driving. All three wheels, and the spare, have cogs glued on them so the wheels are interchangeable. The wheels are built up from Bullseye hubs running on 12mm Allen bolts as axles and use 20” dia. rims. I am using 1.5” wide tires.

Driving the paired wheels through a ratchet for each wheel allows for differential rotation of the wheels during turning while providing a posi-traction effect which preserves traction on slippery surfaces. The Pedicar used a similar approach, and, as a result, was able to climb steep grades on snow covered roads.

The drive shaft is supported by four ball-ball bearings that are in turn supported by two segments of 1.5” dia. tubing. These segments are attached to the 2” diameter tube that makes up the spine of the frame.

Two 1.75” dia. tubes fit over the 1.5” tubes and are supported by four IGUS bushings. Each 1.75” tube has a 13” long, 1.5” dia. tube brazed to it at an angle slightly less than 90 deg. On the other end of this tube a small tube with a 12mm bore is brazed parallel to the 1.75” tube. The small tube accepts the axle for the hub and a nut secures the axle in place.

These tubular wheel beams can rotate around the drive shaft raising and lowering the wheels with respect to the frame. Having one wheel raise and the other one lower causes the vehicle to lean. When leaning, all three wheels remain parallel, and, as a result, during a balanced turn, the loads on all three wheels are radial as they are for a bicycle. A three-link reverser linkage using spherical bearings connects the wheel beams together so they move in opposition.

Below are pictures of the EcoVia 1.1. The seat has yet to be constructed and the cranks are absent.

Below are pictures of the EcoVia 1.1. The seat has yet to be constructed and the cranks are absent.

Below is a photo of the EcoVia 1.4 before it was painted and I began road testing. The numbering indicates it was the fourth iteration of the lean-control mechanism. Comparing the pictures above with the picture below gives an indication of all the modifications that were necessary to make the vehicle rideable. I will skip many details concerning minor aspects of the vehicle's construction for reasons that will become clear later. However, I will discuss the details of the lean-control mechanism because, at the time, I thought it was an innovative approach.

The steering handles were located on either side of the rider. They were capable of two motions. They could be moved forward and back and in so doing rotate the wheel beams down and up respectively, resulting in the vehicle leaning. They could also be moved from side to side for steering. What was novel was that the leaning motion of the handles was coupled to the steering motion through a device I called a Push-Me Pull-You, PMPY. Essentially it was a linkage using two springs that would exert a spring force when it was compressed or extended from a neutral position. So, for a given lean position of the levers, the interconnect linkage would move the steering to a specific location. Through changing the connection point on a coupler linkage, this location of the steering could be adjusted. This steering location corresponded to the neutral position of the PMPY. But this steering position could be overridden by moving the levers laterally, and the PMPY would return them to its neutral position when they were released. As a result, the spring-neutral position for the steering was not always straight ahead but would move according with the lean angle.

The approach when riding the EV1.4 was to adjust vehicle lean to initiate the vehicle to turn. At low speeds, correction to the steering was usually minor or unnecessary. I was happy with the performance and took several four-mile-round trips to the library parking lot to practice turns on Sunday mornings. Low speed testing being considered a success, I began moderate speed testing, say faster than 10mph. While riding along straight road about 15mph, one of the front wheels hit a pot hole. The next thing I knew I was upside down in the ditch. Since the steering and banking were interconnected, the wheel drop associated with the pot hole caused a steering perturbation. The steering went into an unstable oscillation and the vehicle flipped. I pushed the vehicle back home. One advantage of rear-wheel steering is the vehicle is easy to push and steer at the same time. It was little comfort, and I avowed to never ride the EV1.4 again. I felt lucky I didn’t break anything on my person. My son, Kyle, had crashed an earlier iteration of the EV1. At the time I wrote it off to his lack of familiarity with the riding technique. Instead it was merely an early warning that the rear-steering approach was seriously flawed.

In “Bucky and the Urbee” I discuss the difficulty in defending against accusations that the inherent instability of the rear-steerer was responsible for the accident that the claimant just had. I also refer indirectly to my experience with the EV1.4. So, in retrospect, the abandonment of this approach was inevitable.

EcoVia 2.1

EcoVia 2.1

The EV1.4 was dead and there was nothing to do but take the hacksaw to it and make it a front-wheel steer -two-rear-wheel-drive trike. There were three factors that made me optimistic about this approach. I could reuse all of the wheel-drive hardware and much of the frame. I would need a new reversed seat and need to move the bottom bracket above the steering fork. (It didn’t turn out to be quite that simple as I had hoped.) With front-wheel steering the vehicle would be as stable as a typical recumbent bicycle, so I could use free leaning and not actively have to control the leaning. And I had seen a video of the Munzo Tilting Trike which had a similar configuration of rear trailing wheel beams. It seemed to free lean just fine.

To insure that the EV2.1 would lean as much like a bicycle as possible, I kept the wheel beams horizontal when the vehicle was upright and the links for the reverser linkage were vertical and horizontal. I felt this would insurt that the vehicle would lean about a point between the two wheels at ground level. This approach appears to have paid off. On the first coast down my slightly-sloping driveway, I thought the friction in the linkages was preventing the vehicle from leaning. I was wrong! The EV2.1's leaning was so natural that without looking behind me I couldn’t tell that I wasn’t on a bike.

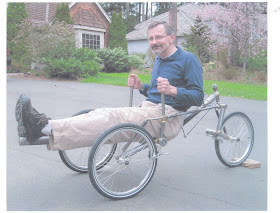

The EV2.1

There was one expected and one unexpected advantage to the front-steering approach. The expected advantage was that the free-leaning drastically reduced the mechanical hardware needed to steer and lean. The unexpected advantage was that the vehicle package became much more compact. The beam holding the crank and the beam holding the fork in the EV1.4 stick out in opposite directions. With the EV2.1, they became one beam sharing the crank-support and fork-support functions, thus shortening the overall vehicle length substantially.

Since the handling was everything I had hoped for, I set about to make some minor improvements.

I added a lean lock that consisted of a section of a disk brake rotor bolted to the horizontal arm of the wheel-beam-reverser linkage. I got this idea from the Munzo trike. To activate the caliper, I used a down-tube shift lever with a tube slipped over it to extend its length. This was attached to the side of the seat. I originally expected to use the lean-lock only for parking purposes. (The front brake lever has a locking feature as well to act as a parking brake.) However, at low speeds it became very convenient to lock the leaning. One forgets how much effort can be associated with balancing a recumbent when going slowly.

I added fenders and I added a frame around the front wheel to support a faring that would tilt forward to enter and exit the vehicle. I got the whole thing painted so I could ride it to church for the annual Earth Day observence. I began to work on the faring.

I put the faring on hold and pulled out the hack saw again.

End of Part 1. Parts 2 & 3 can be found below.