The EcoVia Mk2.4, the best packaged, most aerodynamic version.

For those of you new to the blog or those of you that haven't followed it in a while, the EcoVia project was intended to design and build an all-weather ped-electric commuter tricycle. To reconcile having a narrow width and rider height that was visible to motorists, it would incorporate leaning to improve roll-over-resistance, ROR.

The initial concept was a tadpole configuration with pedal-drive to the two front wheels and a steered- motor driven rear wheel. ( I refer to this as the Dymaxion layout in reference to Bucky Fuller's famous Dymaxion Car)

https://www.blogger.com/blog/post/edit/7497191769424400596/839528612731061124

Now there are two ways to control the leaning of a tricycle. The first is free-leaning, where you balance like a bicycle. The second is to control the lean manually in addition to controlling the steering. Rear-steering bicycles are, at best, difficult to ride. A free-leaning rear-steering tricycle has similar issues, so the initial design intent was to control both steering and leaning with the same motion. Since the amount of lean is a function of steering angle and vehicle speed, this approach can only be approximate at best.

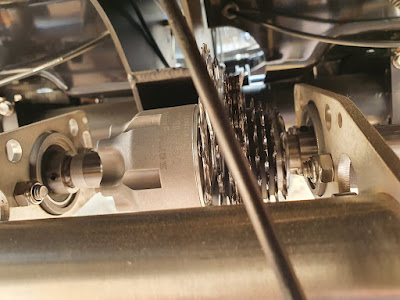

Below is the control mechanism for the EV1.4

Unfortunately, combining leaning and steering can lead to the undesirable phenomenon of bump-steer where, when a steered wheel hits an obstacle, the steering is perturbed unexpectedly. This occurred during a medium speed test run. I was upside down in the road before I knew what hit me. I pushed the trike back home and never road the EV1.4 again.

After a period of reflection I realized the only thing to do was flip the wheel arrangement around into a delta configuration. With the rear steering gone, the delta trike leaned and balanced like a bicycle. I had my design. Several design iterations followed to drop the bottom bracket height and use a large Q bottom bracket to maximize pedal-wheel clearance. EV2.3 resulted.

I had no problems starting and stopping with the EV2.3 until I added a faring.

As often as not, I would tip over before getting started of trying to stop. I had a lever that would lock up the leaning, but the trike was not always upright by the time I activated it. So I came up with a no-lean lock lever. If I was only partially leaned over, pulling the lever did two things. It pushed the trike upright and it locked it in that position.

Given the no-lean-lock lever and it's reduction in crashes, I was confident enough to do some speed tests. I was able to comfortably cruise at about 25mph on the flats. This confirmed the validity of the design concept.

Jerry Onufer, a fellow HPV'er, visited shortly after, and I asked him if he would like to ride the EV2. He declined, saying that a vehicle that mixed being static with balancing would be too difficult for a new rider to master. And there is more than a bit of truth to that. I was riding the EV2 down a highway and forgot that the no-lean-lock was not engaged. I leaned over and weaved across the road. Fortunately there was no traffic or my HPV days would have been over.

So the EV2 was not ready for prime time, and it was back to the drawing board.

I felt that the trike needed to be statically stable and upright for starting and stopping when enclosed in a faring. To address Jerry's concerns, I decided to eliminate free leaning from the design for the EV3. I also added the ability to manually add leaning when executing tight turns.

Six change were incorporated into the EV3.

1. Increase the rear-wheel track from 20" to 30". The static ROR would be 0.45 gees.

2. Add a lean lever to manually lean the trike +/- 17.5 deg. to increase the ROR to 0.8 gees.

3. Change the wheel diameters from 20" to 16".

4. Change all the brakes from calipers to disks.

5. Lower the bottom bracket height by 6"

6. Incorporate a geared hub motor to the front wheel.

Below is my work-in-progress ped-electric trike, the EV3, shown without its faring.

The initial faring in the picture below is 4" higher at the riders head than the final design.

The EV3 is a delta e-trike with the ability to be statically tilted using a long lever on the riders left side.

The seat height is 20" and with a bottom-bracket height of 14.4", the riding position is very comfortable. The rider's head at car level. Cranks are 165mm.

Vehicle weight without the faring is 99 lb. The faring weighs 23 lb.

The battery is 36V which gives a top speed of 15mph. The motor is a geared-hub motor that stops contributing to propulsion at its max speed. The design intent was to have plenty of torque for hill climbing. So much torque, that the front wheel brakes loose if too much throttle is applied when starting.

For comparison the EV3 has a width of 33"(838mm) and a riders head height of 49"(1245mm)

The EV4 is currently in the design phase. Because free leaning has been eliminated, I can return to the EV1 tadpole configuration with a Dymaxion layout. The foot-front-wheel interference is removed. The intermediary bottom bracket and its associated chain will be gone. The beam suspension will be replaced by springs in the lean linkage, in addition to adding suspension to the rear wheel. These, and other integrations will significantly simplify construction and reduce weight.

Wheel pants will streamline the front wheels which will be outboard of the fuselage. In addition the rear-motor wheel will use dual tires to improve traction and insure steering control is maintained in the event that one of the tires goes flat.

Hephaestus

.jpg)

.jpg)