This post was inspired by Graeme Obree, two time world hour

record holder on modified upright bikes and who, at the age of 48, rode his Beastie

streamlined prone bicycle into the record books last September. Obree was

attempting to break the flying 200m sprint for human-powered vehicles which

stands near 83mph. At 56.6mph, Obree came up a bit short. Nonetheless, he did

break the record for a streamlined vehicle using a prone rider position, and

more significantly, in my opinion, he broke the record for a vehicle using a

non-circular pedaling motion.

The two pictures below show a kinematic model of the Beastie's drive mechanism and an enlargement of the resulting pedal path. The path is an elongated ellipse whose major axis is tilted slightly downward front to back.

The two pictures below show a kinematic model of the Beastie's drive mechanism and an enlargement of the resulting pedal path. The path is an elongated ellipse whose major axis is tilted slightly downward front to back.

In the pictures above the cranks rotate in a clockwise

direction and the pedals move in a counter-clockwise direction around the ellipse.

Obree bested the existing record for a linear-drive and

prone-posture streamliner held by Richard Byrne on Steve Ball’s Dragonfly of

54.9mph. The Dragonfly used both arms and legs moving in straight paths for

propulsion. The picture below is from Human Powered Vehicles by Abbott &

Wilson.

For the purposes of the following discussion, I consider

linear motion to include pedals moving in a straight line, pedals moving in large arc over a small

portion of a circle, and numerous curves generated by four-bar linkages having

paths that are significantly longer (in the leg-extension direction) than they

are wide. These coupler curves could be egg shaped, elliptical, figure-eight

shaped among others. In the case of the Beastie, the pedal path is an elongated ellipse.

When someone of a technical bent takes a close look at the

bicycle for the first time, they invariably comment that there has to be a more

efficient means for the body to generate mechanical power than circular

pedaling. Since a runner’s feet don’t go in circles, it makes no sense that

feet going in circles on a bicycle are either natural or efficient. More

often than not, the conclusion is that feet moving in a near-linear path would

be a significant improvement.

The drive mechanisms that will be discussed here fall into

two broad categories, oscillating treadles and constant-torque treadles

Oscillating treadles consist of an input link permanently connected

to an output crank through an intermediate link. When the output crank moves

continuously, the output link moves back and forth between its extreme

positions or oscillates. For a constant crank speed, the speed of the input

link varies over the cycle and often comes to a complete stop at the limits of

travel. By its very nature, one important characteristic of the oscillating

treadle is that one cycle of the input link results in only one rotation of the

output crank. Some form of gearing is usually required between the crank and

the wheel. These systems work best with fixed gearing so that the vehicle

motion carries the pedals through their motion-dead spots.

The crank slider (the

core of every IC engine) is an oscillating treadle. The mechanism used in the Beastie was a offset-crank slider where the slider track is not lined up with the crank pivot. In addition, the pedal is located above the connecting rod. This produces a relatively horizontal-flattened ellipse located above the crank center, which accommodated the rider being located above the crank center.

Because friction associated with the slider can waste

energy, a rocker link often replaces the slider for mechanism used for human

power generation. The connecting rod moves through a short segment of a large

arc instead of a straight path.

When used by Kirkpatrick McMillan in the mid 1800’s the

crank-rocker mechanism was the first bicycle drive.

Oscar Egg, a world-hour record holder on upright bikes, used

a crank rocker for a streamlined recumbent design. Notice that this is a

fixed-gear system where the vehicle motion prevents the pedals from stopping at

their dead spots.

And the prolific Gary Hale produces his Glider which employs

a crank-rocker.

And the crank rocker is still used to propel most children’s

kiddie cars.

Referring to the crank-rocker diagram again, if the pedals

are located at point A, they will travel in a circle. If they are located at

point B, they will travel in a large arc. If the pedals are attached to the

connecting rod, at point C, they will travel through a hybrid of the circle and

the arc, an elongated teardrop. These coupler curves have the advantage that

the pedal continues to move at the ends of the stroke conserving some of the

kinetic energy of the moving limbs. The downside of locating pedals on the

connecting rod is the pedals are connected to the frame through two pivotal

joints instead of one. This can result in more flexible connection (read

sloppy) than a connection through only one joint.

Another oscillating treadle mechanism is a rocking slider.

The slider is attached directly to the crank instead of through a connecting

rod. To compensate for the transverse motion of the crank, the slider must

rotate about its sliding point.

The K drive,

nicknamed because Miles Kingsbury used it on one of his streamliners, is

derived from an elliptical trammel. The mechanism can produce a straight pedal

path but as configured here it produced a long-thin ellipse. The pedal path produced by this configuration is very similar to that employed in the Beastie.

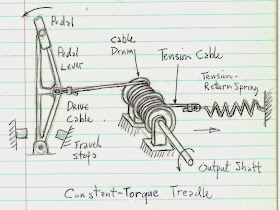

The other drive mechanism that will be discussed is the

constant-torque treadle.

Unlike the oscillating treadle, the ratio of input lever

speed to output shaft speed is constant (and as a result, so is the torque). There

is a one-way clutch located in the cable drum which allows the input lever to

return to the beginning of stroke without reversing the motion of the output

shaft. Additional stops must be inserted to limit the input link travel. The

ratio of input link motion to output shaft motion can be adjusted by changing

the position that the cable attaches to the input lever. This is one big

advantage of the CTT; it can incorporate a very simple means to achieve multiple

gearing. Some form of return device, usually a spring, must be used to reverse

the input link motion at the end of travel.

The CTT is the mechanism most often reinvented by those who

would improve the design of the bicycle propulsion mechanism. It is also has

been the most prevalent drive system after the rotary crank. It was used on the

American Star pre-safety bicycle in the late 1800’s. Paul De Vivie, aka Velocio, the father of the derailleur, experimented with CTTs in the early 1900's. Below is one of his own designs. Depending on where you placed you foot on the treadles, you could vary the effective gear ratio of the drive. A cable connected from one treadle to the other insured that the non-driving treadle moved up while the driving treadle moved down.

You can still find numerous prototypes today. Steve Ball’s Dragonfly used a modified version of the constant-torque treadle, as did the Pedicar.

You can still find numerous prototypes today. Steve Ball’s Dragonfly used a modified version of the constant-torque treadle, as did the Pedicar.

There are several reasons why a person designing a

human-powered vehicle (HPV) would use a pseudo-linear pedaling motion.

1. There is interference between the pedals and the

steered wheel with circular pedaling motion.

W. D. Lydiard used a rocking-slider mechanism to reduce

pedal-steered wheel interference on his entry for D. G. Wilson’s 1968

Human-powered-vehicle design competition, the Bicar. The picture is from the

first edition of Bicycling Science by Witt & Wilson.

I experimented with a crank-rocker mechanism in an attempt

to reduce pedal-steered wheel interference in my EcoVia commuter trike design.

I employed a two sided pedal in this design. The outboard

side of the pedal holds the rocker link that supports the pedal. In this

location it is spaced wide enough to clear the turning wheel. The inboard side

of the pedal holds the connecting rod which is located above the wheel and

includes a bend to clear the wheel. This is my interpretation of D.G. Wilson’s

crank-rocker concept sketch for a recumbent bicycle.

2.

The foot and knee moving through a pseudo-linear

motion take up less volume than circular pedaling.

A classic use of linear motion for this reason is in the

Pressodyne streamliner form the late 1970’s. The article is from the Spring

1980 issue of Human Power.

Here are a few highlights relevant to the current

discussion. The pedal motion was truly linear using rollers to support the

pedal arms. The stilts-version of the Pressodyne used cables that connected the

pedals to one-way clutches. This was a constant-torque treadle approach but no

efficient means of limiting pedal travel was provided and the pedals crashed

into the stops. The three-wheeled version used a crank-slider approach which

was much smoother. The smoothness was also due to the fact that there was also

no freewheel in the system (fixed gear). So, when the vehicle moved the pedals

moved and there was no issue with dead spots in the motion.

The shape of the Pressodyne was not far of the mark for the

optimal streamliner shape. Notice the similarity with probably the epitome of

streamliner design, the Varna Tempest. The tempest required a bigger nose to house

the circular pedaling but had a smaller canopy.

And reducing swept volume of the leg and foot is undoubted

the reason Obree employed a teardrop-pedal path in his Beastie.

3.

The linear drive is simpler that a pair of

cranks, a chain and two sprockets.

The Mergamobile was a pretty simple approach as was the 1921

J-Rad. One used the different pedal locations to obtain three different gear

ratios. Both design use constant-torque treadles.

4.

The linear drive is more efficient than circular

pedaling motion.

The constant-torque treadle is the most popular design

proposed for improving the efficiency of bicycle propulsion

.

The most publicized use of a constant-torque treadle was in

the 1973 Pedicar.

Trevor Harris, a race car designer and designer of the

iconoclastic Can Am Shadow produced the Harris Vertical in the mid 1970’s.

The Alenax Trans-bar bicycle was commercially produced in

the 1980’s.

The Alenax was an almost a direct copy of the Svea

manufactured in Sweden in the late 1890’s. Paul de Vivie, Velocio, the pioneer

cyclo touriste, supposedly experimented with the Svea in his quest to find the

perfect touring bicycle.

Notice both the Harris and the Alenax have adjustable

cable-attach positions on their pedal levers for variable gearing and both have

synchronization mechanisms to move the pedals in opposition to each other. The

Harris uses a rocker linkage and the Alenax uses a cable loop.

When discussing the reinvention of the constant-torque

treadle, I can’t help but hear Santayana’s quote “Those that cannot remember

the past are condemned to repeat it”. In this case “know the past” is more

appropriate. The following optimistic declaration that the bicycle has been greatly

improved is a fun foil to discuss the shortcomings of constant-torque treadles

.

It also may be useful for the reader to review the section

on Power in the following post.

Let us begin with why the constant-torque treadle appears to

be more efficient than the rotary crank. Assume the rider exerts a force of F

in a straight line with each leg. With a rotary crank the torque that is

transferred to the wheel is F*sin(theta) where theta is the crank angle. The

average torque over a cycle is 2F/Pi or .64F. So from the start, from a torque

standpoint the CTT is 57% more efficient.

Unfortunately there are two factors that prevent this

increase in torque from being converted to an increase in power

.

Our linear-motion bicycle salesman states that his drive

develops full power from the beginning. That is not true. At the beginning of

the pedal stroke, the foot is stopped but the output shaft is moving at full

speed. It takes a portion of the pedal stroke for the pedals to catch up to the

output shaft and during this catch-up phase no force is being produce and, as a

result, no power is produced. Both the Dragonfly and the Harris Vertical

incorporated cams to gear up the pedal stroke in the beginning to allow the

pedal speed to more quickly match the speed of the output shaft. However the

cam must be designed for a specific gear ratio. So on the Harris Vertical, the

cam will only be effective for around one gear selection.

Another problem is the pedaling speeds that can be sustained

with linear drives are significantly lower than those that can be sustained

with a rotary crank. This is due to the kinetic-energy fluctuations of the

moving limbs. With linear motion the foot stops at the pedal extremes and the

kinetic energy drops to zero. With circular cranks, speeds of 300rpm have been

achieved because the kinetic energy is relatively constant. Since power moves the bike and since power is

the product of torque times angular velocity, lower pedal speeds result in

lower power levels.

The rider is very diplomatic when asked for his impressions

riding the linear bicycle. He says it is much better than the first prototype

but he doesn’t say it is better than a regular bicycle.

The linear bicycle riders comments that his leg muscles have

gotten bigger riding the linear bicycle is an indication that things have

become less efficient as opposed to more efficient. When Paul Dudley White,

President Eisenhower’s personal physician and bike advocate, rode the Pedicar,

he also noticed that it put more strain on the thigh muscles.

One factor that is inconsequential for light-weight vehicles

like bicycles but becomes a problem for heavier commuter vehicles is that with

the CTT drive, the vehicle cannot be rolled backward. The one-way clutches lock

up going backward causing the input levers to jam against the motion stops. This

is the reason the Pedicar incorporated a reverse gear at the cost of a

significant increase in complexity of the transmission.

There appears to be a means of accelerating the foot at the

beginning of the pedal stroke that remains effective throughout an adjustable

gear range. When cams were used above, they were inserted in series with the

drive cable. I advocate using springs in parallel with the drive cable.

Assume a synchronizing linkage is used to connect the pedals

and move them in opposition. Springs are

located so each pedal compresses the spring as the pedal is pushed forward. The

springs exert no force at the beginning of the stroke and exert maximum force

at the ends of the stroke. Assume the force at the end of the stroke is 2*F.

The combination of the synchronizer mechanism and the

springs results in the force vs. pedal position shown in the first graph. With

no external load, the zero-force position for the pedals will be at midstroke. From

the beginning of the stroke to midstroke, the springs act to move the pedal

forward, accelerating the foot. From midstroke to end of stroke, the springs

resist forward motion and add to the force required to propel the vehicle. If

the average force required to drive the vehicle is equal to F, then each pedal

sees a force vs. displacement curve shown in the second graph. The pedal

encounters an increasing force from the beginning to the end of the stroke.

Since the leg can exert more force as it extends, this matches the pedal force

to the legs ability to generate force.

One approach to determining the spring rate for theses

springs is to select them so a resonant condition occurs with the moving leg

mass. Let us say the moving leg mass for each leg is ½ the mass of the thigh

plus the mass of the shin and the foot. From anthropometric data, that comes to

about 13.5% of body weight. With a 170lb. rider that gives a moving mass of

23lb. Let the resonance be at 75rpm or 1.25Hz. That requires a spring rate of

approx. 4lb./in. Assume a pedal stroke of 180mm or 7in., then F is 28lb.

28lb at 75rpm and a 14” stroke corresponds to 110W. So at a

power level of 110W, the pedal force is zero at the beginning of the stroke and

56lb. at the end of the stroke. The

spring rate could be increased so negative to low forces are encountered at the

beginning of the stroke for power levels higher than 110W.

After thinking so much about the Pedicar, I couldn’t resist speculating

about a drive-system redesign that would address its shortcomings. I also

assumed it would be a banking-three wheeler with front steering. As a result

the pedal levers are two-piece with the support link outboard of a two-sided

pedal and the input link inboard of the pedal. ( See my crank-rocker design for

the EcoVia, above.)

I have included a

synchronizer linkage and accelerator springs to smooth out the pedaling.

Instead of the Pedicar’s five speeds covering a range of 6:1, I use a shifting

quadrant on the input link that can be rotated over an 8:1 ratio, but a range

divided into 21 steps. The 8:1 ratio using 16t freewheels as the one-way

clutches required a gear-up mechanism. I incorporated a forward and reverse

gear set into that mechanism. Recall that, since the one-way clutches prevent

the vehicle from being pushed backward, some means of disengaging the drive or

having a reverse gear is necessary to move the vehicle backwards

.

When I stood back and looked at the design, I realized that

although it addressed the Pedicar’s design deficiencies, it is probably no-less

complicated than the Pedicar’s drive, and no lighter in weight. Since the cost

of all-weather human-powered commuter vehicles seems to be the greatest factor preventing

their popularity, this would not be a good design approach. An ultra-wide range

cassette with a single chainring is cheaper, lighter weight and allows the

vehicle to be pushed backwards.

So the next iteration of the EcoVia will pass on the

constant-velocity treadle.

There is one circumstance where the constant-torque treadle performs

significantly better than conventional circular pedaling is when climbing the very

steep hills typically encountered in mountain biking. Outstanding hill climbing

performance is mentioned in regard to the American Star of the late 1890s and

the Pedicar.

A more detailed explanation of hill-climbing problems associated

with conventional circular pedaling can be found in the Kinetic Energy and

Cyclic Energy Storage section of the Why Hill Climbing is Hard post.

From the standpoint of power generation efficiency (mechanical

power out/oxygen in) producing power in pulses interspaced with rest periods is

better that producing power continuously. The extra energy produced during the

pulses is used up during the rest periods and this energy is stored in changes

in the kinetic energy of the vehicle. If the vehicle speed drops below a

certain level, the power cannot remain pulsatile and the rider must produce

power around the complete pedal cycle instead of the usual pulses produced from

1 to 5 o’clock in the pedal cycle.

The constant-torque treadle is cadence limited but this is

not a problem because the cadences associated with steep hill climbing are

low. The dead spots in the pedal cycle are only momentary with the CTT and

torque is produced for almost all of the cycle while the foot only moves

through its normal force generating range. Adding acceleration springs just

improves the performance assisting foot motion at the beginning of the pedal

stroke.

Come to think of it, a few of the restored Alenax Trans-bar

bikes were sporting mountain-bike tires.

If Graeme Obree had propelled his streamliner with

convention circular pedaling, he probably would have gone faster, but he would

only have a prone-rider record. I believe the linear-drive speed record is technically

more interesting.

Hephaestus