Many of my small number of followers know of my fascination for the 1973 Pedicar that made its debut in the US during the gas crisis. The Pedicar was revolutionary, but unfortunately, less than 20 units were ever built.

The post below goes into depth on the Pedicar's construction.

https://lefthandedcyclist.blogspot.com/2012/04/pedicar-technology.html

The arrival of the Pedicar started my quest to design my own all-weather pedal-powered commuter vehicle, and I was presumptuous enough to think I could improve on the Pedicar.

My list of requirements for the design is listed below

1.The vehicle should have three or more wheels for stability on slippery surfaces.

2. It should place the rider's head at the height of a typical automobile.

3. It should be narrow enough to comfortably fit in a bike lane. I can be more specific on this. It should fit between barriers spaced 36" apart, so assume a maximal width of 34".

4. It should not overturn when cornering. Assume a tipping resistance of .7 gee.

4. It should be enclosed to protect the rider from the elements.

5. And for traction on slippery surfaces, it should drive at least two wheels.

The Pedicar met all the requirements, except the width being approx. 36" wide. In current dollars the cost was $3620.

The Pedicar's technical failing was its linear pedal drive. The pedal levers pulled chains that ran over freewheels. This resulted in a constant torque at the wheels. A freewheel on each half-axle acted as a posi-traction differential. It had five forward speeds and a very impressive reverse gear. Braking was with twin discs on the rear wheels.

It was 82" long with a 58" wheelbase and weighed 125lb.

The chassis was an "I" shaped aluminum weldment with the long section supporting two crossbeams. There was no formal suspension and shocks were absorbed by the twisting of the central section.

The Quadvelo is 34", 98" long with a wheelbase of 69". It weighs 210lb. with doors and battery. It has a number of similarities to the Pedicar.

Both used four 20" wheels. The Quadvelo's chassis is made up of a "T" shaped aluminum weldment. Perpendicular carbon-fiber leaf springs support the front wheels at the front of the "T" and longitudinal leaf springs support a transverse beam that, in turn supports the rear wheel axles. The seat can slide along the longitudinal leg of the "T".

The seat's angles are adjustable and the handlebars are mounted below the seat.

The pedals drive a Sachs RS925 motor.

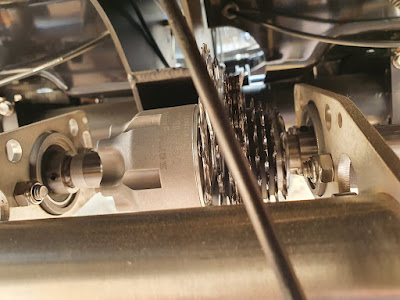

At the rear axle, the Quadvelo used a nine-speed freewheel cluster attached to a Samagaga differential . Two splined axle shafts are attached to the rear hubs. In the lower left of the picture you can see the longitudinal carbon-fiber leaf spring that supported the axle assembly. Also connected to the axle assembly are two dampers that are connected to an "L" shaped extension of the chassis. Braking is done by four hub brakes all around.

The carbon-fiber leaf springs that support the front wheels is shown below.

The Quadvelo is 92" long with a wheelbase of 69". The vehicle width is 33.5" Vehicle weight is approx. 210lb and the cost of the basic model with doors is $13,2800.

Overall, I think the Quadvelo is well designed, but I think it could be improved. Looking at the assembled chassis without the body, I think that the wheelbase could be significantly shortened by at least 10" For reference, I am riding a delta trike with a wheelbase of 52"

Another concern is the cost. I don't know who would spend over $10,000 for what is basically an all-weather tricycle, limited to 15mph. If the Pedicar was updated with a derailleur transmission, hub brakes and a crank-mounted motor drive, the present day cost would still be less than $5000. So some of the Quadvelo's complexity should be eliminated to drop the cost.

Of course, the biggest problem with the Quadvelo is that four-wheel pedal assisted vehicles do not qualify as E-bikes in North America. The regulations state the vehicle can not have more than three wheels.

Now a quad vehicle has 50% more roll-over resistance than a trike having the same track (lateral wheel spacing). So it is difficult to design a trike to meet my design requirements without having it be able to lean into corners. I won't discuss leaning trikes here, since I have written about them ad nauseum in other blog articles. So a quad layout, despite the complexity of another wheel, is a preferred layout for an all-weather, pedal-assisted commuter vehicle.

If E-bike speeds were all limited to 20mph, then I would recommend that four wheels would be allowable and require the width of both three and four wheelers to be 34" or less. Unfortunately, I feel that the 28mph speed limit for class 3 E-bikes is unacceptable with a vehicle as large as the Quadvelo.

Think of the potential damage a 400+lb vehicle could cause if it hit something or someone at 28mph.

Class 1 & 2 E-bikes can go up to 20mph and my experience is that when my leaning trike, that is plenty fast.

Hephaestus

.jpg)